Top 7 Things to Know About Smart Manufacturing

- Category: Manufacturing

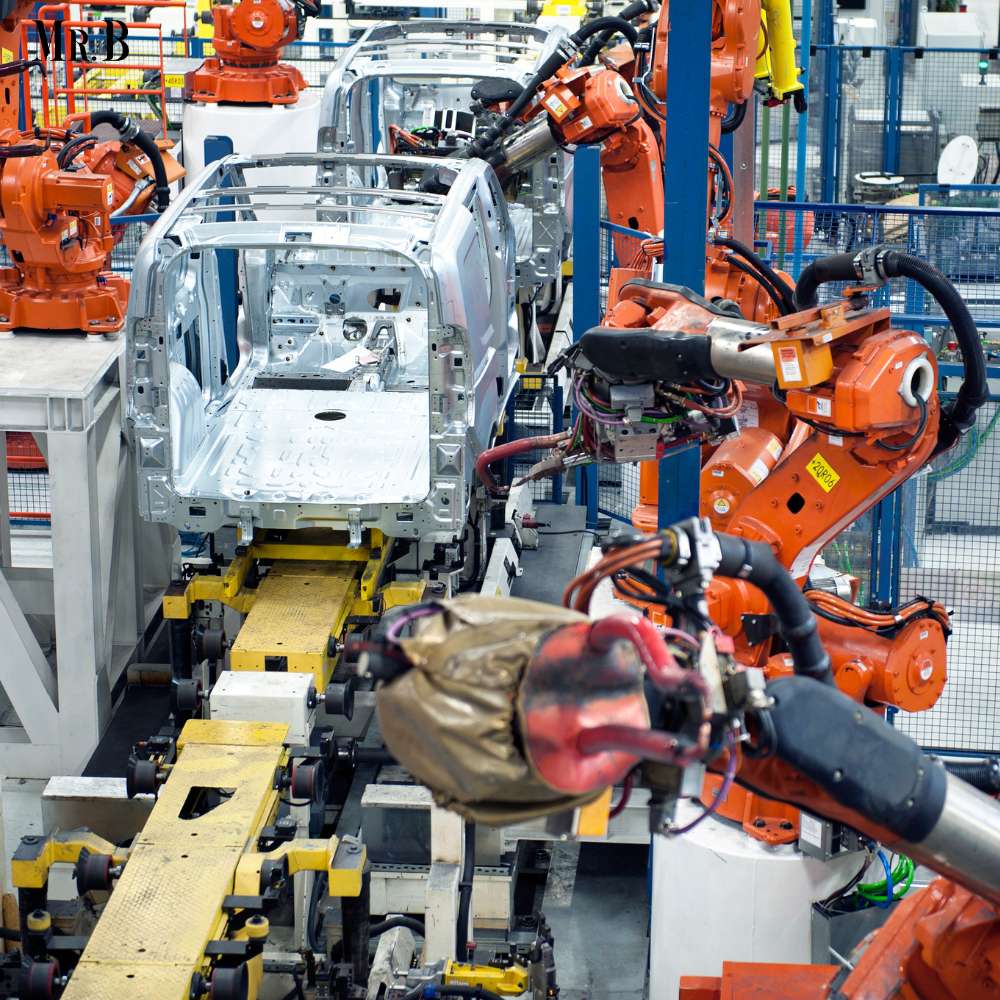

The invasion of smart manufacturing has compelled factory owners to reschedule their plans. They need to be smart enough to fully leverage the technology smart manufacturing technique offers. It is a cluster of enhancing the process of manufacturing which will reduce costs and help to enhance the process. It is a process which accommodates data, processes, technology, and human communication to transform the manufacturing process. This technology helps to adopt rigorous and robust operations which much almost zero errors. The output received from such technology is reliable enough. It is reshaping the industrial landscape, revolutionizing how factories operate in the modern era.

Let’s explore more on Top 7 Things to Know About Smart Manufacturing:

1. Smart Manufacturing Enhances Efficiency

It isn’t just a buzzword; it’s a game-changer for factory efficiency. By harnessing real-time data and advanced analytics, it optimizes production processes, minimizes downtime, and significantly enhances overall productivity. This translates into reduced operational costs and improved resource utilization, making this a cost-effective choice for factories.

2. Cost Reduction and Resource Optimization

Factories embracing smart manufacturing benefit from substantial cost reduction. This approach identifies inefficiencies and minimizes waste throughout the production process. Resource optimization is another key advantage, as it enables factories to use resources more efficiently, conserving energy and raw materials. In a world increasingly concerned with sustainability and resource scarcity, this is a critical factor.

3. Quality Improvement

Smart Manufacturing ensures consistently high product quality. Through the use of advanced sensors and analytics, factories can monitor and maintain product quality in real-time. This proactive approach reduces defects and rework, enhancing overall product quality and customer satisfaction.

4. Customization at Scale

Modern consumers demand personalized products, and smart manufacturing delivers. Factories can tailor production processes without compromising efficiency, meeting the growing demand for customized goods. It allows for flexibility and adaptability in production, which is essential in today’s dynamic market.

5. Predictive Maintenance

Smart Manufacturing systems are equipped to predict equipment failures. By analyzing real-time data, these systems can identify potential issues before they become critical, enabling proactive maintenance. This not only reduces downtime but also minimizes costly equipment breakdowns and repairs.

6. Data-Driven Decision-Making

Access to real-time data is a cornerstone of smart manufacturing. This data empowers factory managers to make informed decisions quickly. Whether it’s optimizing production schedules, adjusting equipment settings, or responding to changing market conditions, it enables data-driven decision-making, resulting in better outcomes.

7. A Competitive Edge

In a world characterized by global competition, it is the key to staying competitive. It provides the agility, efficiency, and quality control necessary to excel in a rapidly evolving global market. Factories that embrace this technology have a distinct advantage over their counterparts that do not.

Why Smart Manufacturing Is Essential for Factories?

Now, let’s explore why this is not merely an option but a necessity for factories:

1. Global Competition:

Factories must compete with counterparts worldwide. Smart Manufacturing offers the agility and efficiency required to stay ahead in a globalized market.

2. Customer Expectations:

Today’s consumers expect customization, quality, and rapid delivery. It allows factories to meet these expectations effectively.

3. Industry 4.0:

We are in the midst of the fourth industrial revolution, characterized by digital transformation. Factories that fail to adapt risk becoming obsolete.

4. Resource Scarcity:

It helps factories optimize resource use, which is crucial in a world facing resource scarcity and environmental challenges.

5. Regulatory Compliance:

Increasingly stringent regulations demand meticulous monitoring and control of manufacturing processes, a task streamlined by smart manufacturing.

6. Workforce Development:

It can enhance worker skills and job satisfaction, attracting and retaining talent in a competitive labor market.

7. Supply Chain Resilience:

This type of manufacturing aids in building resilient supply chains, vital for surviving disruptions like pandemics or natural disasters.

Execution Techniques of Smart Manufacturing in a Factory Setup

Implementing the technology within a factory involves a series of essential steps:

1. Data Collection and Integration:

Collect data from various sources, including sensors, machines, and existing systems. Integrate this data into a unified platform for analysis.

2. IoT Sensors:

Deploy Internet of Things (IoT) sensors throughout the factory to monitor equipment, processes, and environmental conditions.

3. Data Analytics:

Utilize advanced analytics to extract insights from data, enabling predictive maintenance, process optimization, and quality control.

4. Connectivity:

Ensure robust network infrastructure to support data transmission and communication between devices and systems.

5. Automation:

Introduce automation technologies like robotics and AI to streamline processes, reduce human error, and enhance productivity.

6. Cloud Computing:

Leverage cloud platforms for data storage, processing, and accessibility from anywhere, enhancing scalability and flexibility.

7. Cybersecurity:

Implement robust cybersecurity measures to protect sensitive data and ensure the integrity of these manufacturing systems.

8. Employee Training:

Provide training to factory workers to operate and troubleshoot Smart Manufacturing systems effectively.

9. Continuous Improvement:

Establish a culture of continuous improvement, using data-driven insights to refine processes continually.

Conclusion:

Smart Manufacturing is not just about improving factory processes; it’s about securing the future of manufacturing itself. The value-based advantages it offers, including efficiency enhancements, cost reductions, and quality improvements, make it a necessity for factories looking to thrive in today’s competitive landscape. To succeed, factories must embrace data-driven decision-making, IoT sensors, and AI integration while focusing on sustainability and adapting to emerging trends. This type of manufacturing is not a choice; it’s a strategic imperative for factories aiming to remain competitive and innovative in the digital age.