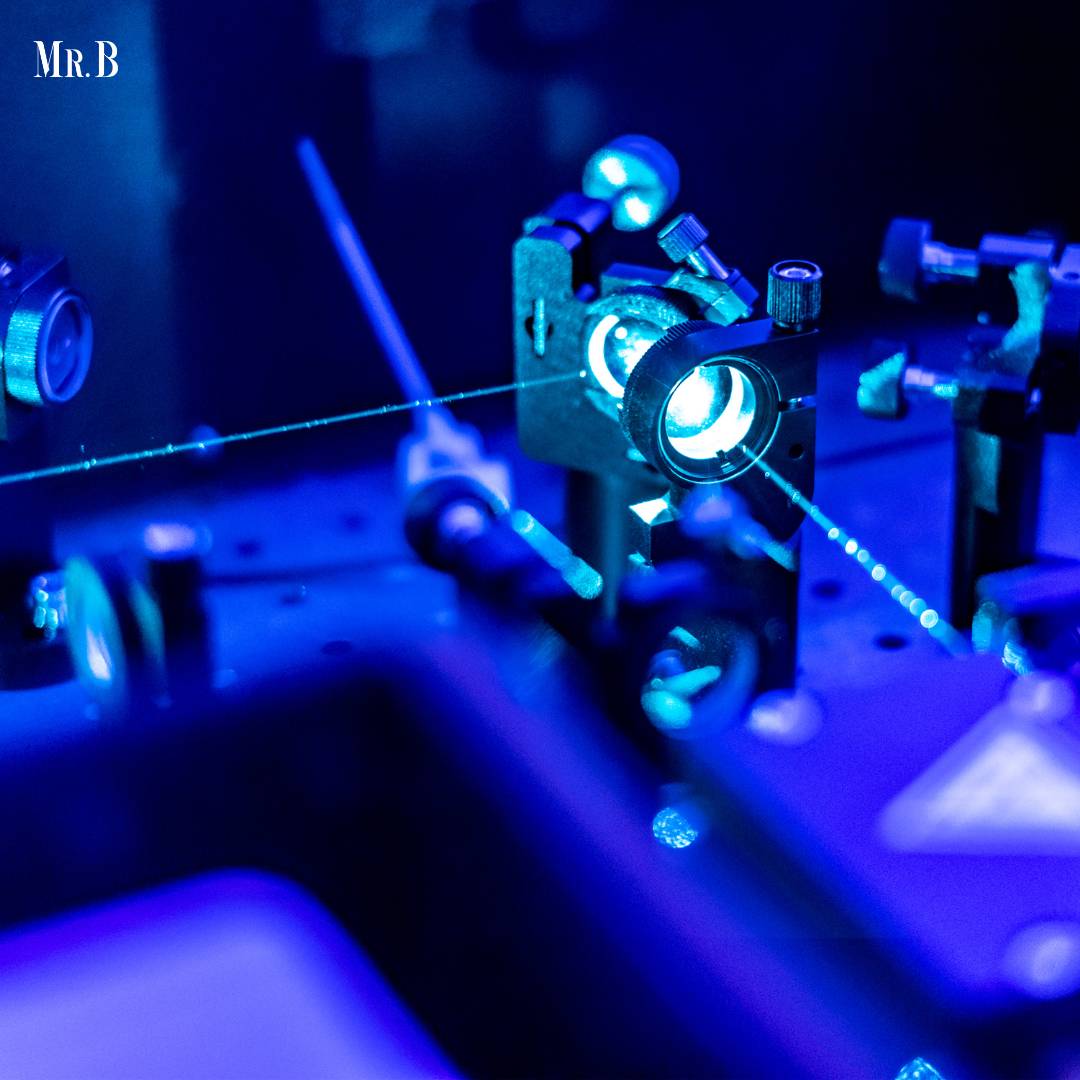

When we talk about the laser optics, the mind quickly goes to the kind of light that has very short bandwidth and power, and the one that is pretty coherent. These specifics need to be taken into consideration when you are using any optics with laser beams.

Here Are Some Steps for Laser Optics in 2025:

1. What exactly are laser optics?

Speaking from a physics point of view, the laser optics are certain optical elements which are designed for and vastly used for laser applications. The light beams that come from a laser are usually more intense than the regular light emission, while also being uni-directional.

So, when you want to focus, filter, redirect or transmit a laser beam, you are required to use specific optics that are specially designed for the purpose of the laser. The elements for a continuous wave (CW) laser pulse can be different. Like the same component used for a 266nm laser may not be suitable for a 1064nm laser.

Simply put, the laser optics are the devices and components which are designed to use for a specific laser.

2. What are the requirement of laser optics?

The bandwidth and power of laser optics are quite limited. They require specialized laser optics because they are significantly more complicated than ordinary light. With laser light, normal optics will not function properly. Glass alone won’t always suffice for laser optics because they often need to be of the highest calibre. As a result, it is held to the highest standards possible for quality.

3. What is laser-induced damage threshold? (LITD)

Laser Induced Damage Threshold (LITD) generally is the amount of energy which an optical can take without causing any damage to it. This is expressed in J/cm2. For lasers with high powers, considering LITD is important. This is because it should be designed and adjusted for a certain wavelength. For the purpose of designing process, it is important to know if the laser is CW or Pulsed.

Laser optics are known to achieve a 100% transmission rate. In order to reach this perfect rate, there are a number of things you can do.

For example:

The material that you use to make the laser optics should be very pure. Lasers tend to destroy any kind of impurities, and can therefore damage the glass. The optics also need to be polished well so as to reduce any kind of absorption. Also, you need to make a point that the element is kept clean at all the times, and that it is preferably cleaned in clean rooms.

Another very important point that you need to keep in mind is that you have added coating to the optics. An anti-reflection nature of coating helps largely to improve the transmission. The best kind of coating recommended is the IBS coating as it helps to enable a higher layer density.

4. How is the LIDT for laser optics measured?

It requires costly equipment and destructive testing, making measuring LIDT difficult.

The procedure is shining a laser beam onto the optic that will be checked and visually assessing any potential damage. To fine-tune the LIDT value, several tests can be run on the same optics.

There are general guidelines for extrapolating a LIDT from one type of laser to another, but they are not very accurate and cannot be used as the foundation for an optical design. As previously stated, a LIDT is linked to a specific type of laser, so one should be able to test a LIDT with a corresponding laser device.

Due to the destructive nature of the testing and the cost of laser optics, LIDT is frequently backed by the adherence to other requirements (material, kind of coating, polishing, cleanliness).

5. How can laser optics LIDT be optimized?

A virtual element with 100% transmission would not exhibit LIDT since damage threshold and energy absorption are correlated. The following components must be produced and chosen in laser optics to get as near to 100% transmission as possible:

Raw materials should have strong transmission at the chosen wavelength and almost no impurities because they will cause the optics to degrade as they are heated by the laser beam energy.

Surface: The higher the transmission through the optics, which results in a lower absorption, the better the polishing. One method to enhance LIDT is the use of extremely polished objects.

Coating: An anti-reflect coating will increase transmission; in laser optics, they are typically sharply focused on a particular wavelength (with a “V”-shaped reflection curve) in order to attain the lowest reflection values. IBS coating is preferable to evaporation coatings because it allows for a higher layer density and thus lower absorption of water and contaminants.

Cleanliness: LIDT is dependent on the optical element’s surface condition; dirty components will perform worse in terms of their damage threshold. Cleanrooms are frequently used for the production and handling of high power elements.

6. Which Optical Materials are Best Used for Laser Optics?

As already seen, it is very important for companies to choose good quality optical material that has high transmission in the wavelength range of the laser. In addition to this, it is also important for the companies to select materials that have low impurities. Some of the examples of materials that can be used for laser optics are:

- ZnSe for laser in the MidIR (8-12µm)

- CaF2 Nd:YAG lasers (266nm & 4µm), due its low absorption it can stand high LIDT it is therefore often used for Eximer lasers.

- MgF2 : for UV and Eximer lasers.

- For C02 lasers (10,6µm) : Zinc Selenide (ZnSe), Germanium (Ge), Galium Arsenide (GaAs) and Silicon (Si)

- N-BK7/ H-K9L are also good substrate for laser optics providing that they are not used in too high power.

- Fused silica is often used for laser optics due to it’s high purity (more than 99,99%)

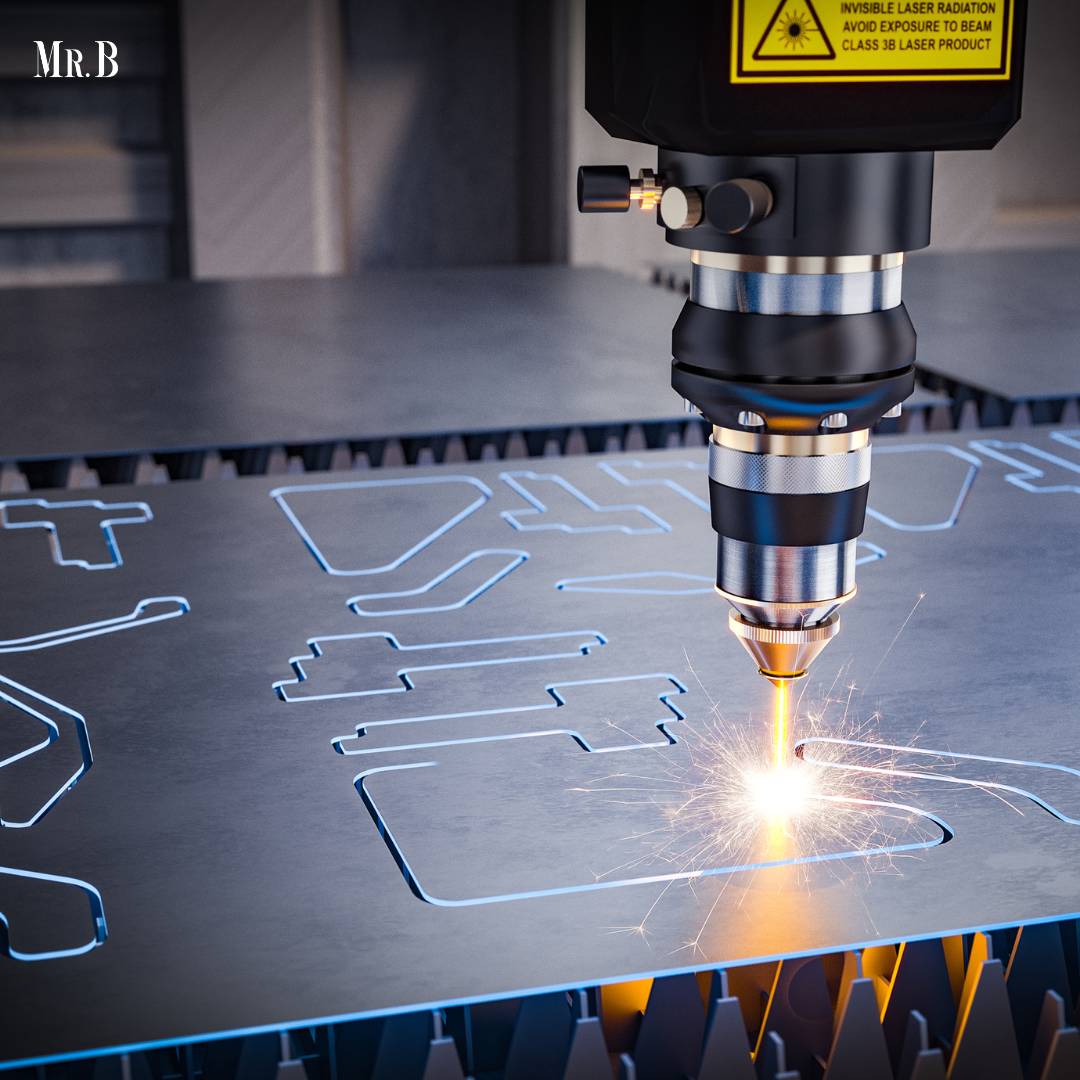

7. What are the different kinds of laser optics components?

- Lens- focusing of laser beam

- Aspherical lens- better focusing of laser beam

- Laser mirrors- Redirection and distribution of laser beam (for example for scanning applications)

- Laser cavity mirrors- Total reflection mirrors & output mirrors

- Filters- Improve the quality of the beam or reduce beam intensity

- Laser windows- Protect optical equipment from external elements

- Wave plate- Differentiate laser beams

- Beam splitter- split a beam in two lower intensity beams