In the intricate landscape of modern technology, electronic manufacturing processes play a pivotal role in bringing innovation to life. This article delves into the depths of electronic manufacturing processes, dissecting their pros, and cons, and addressing frequently asked questions to provide a comprehensive understanding.

The Essence

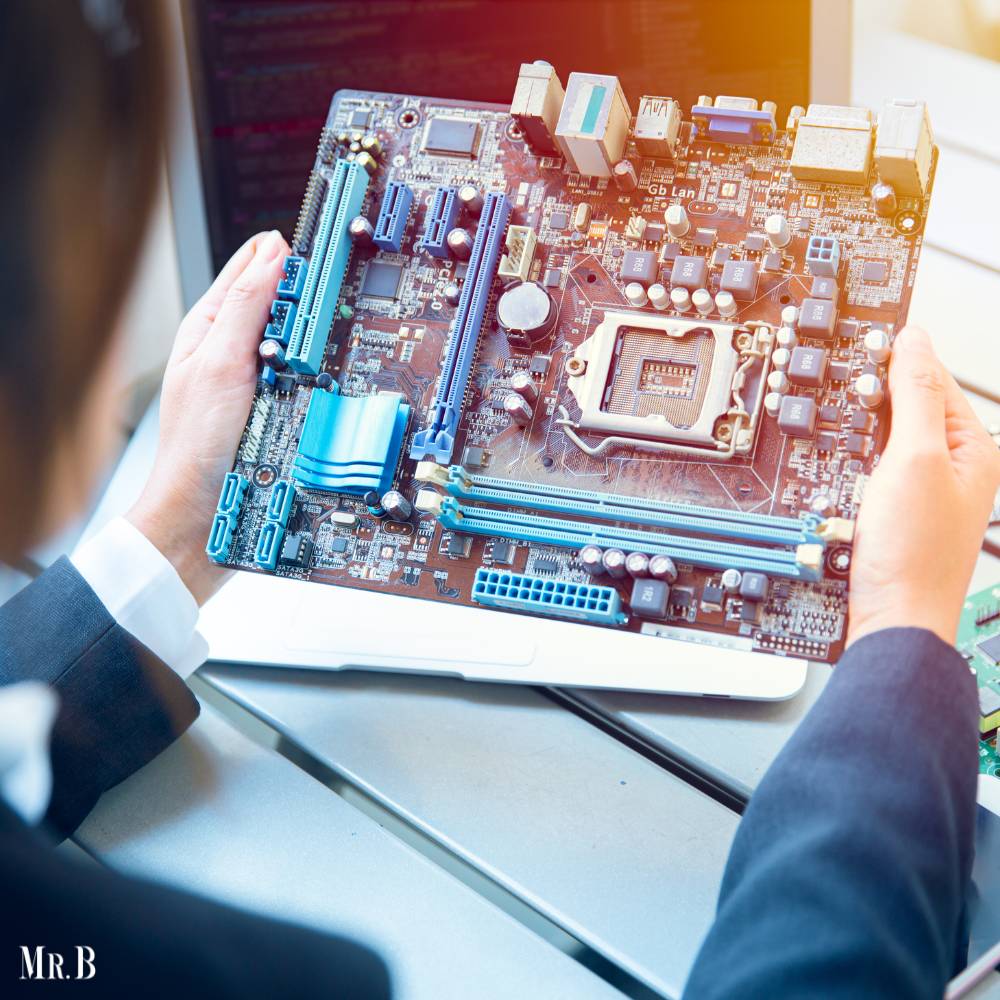

These processes encompass a series of steps involved in the creation of electronic devices, from the initial design to the final product assembly. These processes are intricate, involving various technologies and methodologies to ensure the production of efficient and reliable electronic components.

Pros

- Precision and Accuracy

Electronic manufacturing processes leverage electronic manufacturing processes ensuring precision and accuracy in the production of components. This leads to the creation of high-quality electronic devices with minimal margin for error.

- Automation for Efficiency

The incorporation of automation in electronic manufacturing processes streamlines production, enhancing efficiency and reducing manual errors. Automated systems can handle repetitive tasks, allowing human resources to focus on more complex and strategic aspects.

- Innovation in Design

These processes facilitate continuous innovation in the design of electronic components. Manufacturers can experiment with new materials, shapes, and functionalities, pushing the boundaries of what electronic devices can achieve.

- Mass Production Capability

The processes are designed to accommodate mass production needs. This scalability ensures that electronic devices can be produced in large quantities, meeting the demands of the market.

- Improved Cost Efficiency

Efficient processes, coupled with economies of scale, contribute to improved cost efficiency in electronic manufacturing. This can lead to more affordable electronic devices for consumers.

Cons

- Environmental Impact

The electronic manufacturing industry is known for generating electronic waste, contributing to environmental concerns. Proper disposal and recycling methods are crucial to mitigate the negative impact on the environment.

- Initial High Setup Costs

Implementing advanced electronic manufacturing processes often requires significant initial investments in technology, equipment, and skilled personnel. This can pose a challenge for smaller manufacturers or startups.

- Complexity of Quality Control

Ensuring the quality of electronic components can be challenging due to the complexity of the processes involved. Rigorous quality control measures are necessary to identify and rectify defects during production.

- Rapid Technological Obsolescence

The fast-paced nature of technological advancements can render certain electronic processes obsolete relatively quickly. Manufacturers must adapt to evolving technologies to stay competitive.

- Dependency on Global Supply Chains

These manufacturing processes often rely on global supply chains for raw materials and components. Disruptions, such as geopolitical events or natural disasters, can impact the availability and cost of these resources.

How do electronic manufacturing processes help in minimizing costs?

- Automation for Efficiency

One of the primary ways these processes minimize costs is through the integration of automation. Automated systems, equipped with precision machinery and robotic technologies, significantly reduce the reliance on manual labor. This not only accelerates the production cycle but also minimizes the occurrence of errors associated with human intervention.

Automation allows for consistent and standardized processes, ensuring that each electronic component is manufactured with the same level of precision. By reducing the margin for error, manufacturers can avoid costly rework and warranty claims, ultimately contributing to substantial cost savings.

- Scalability and Economies of Scale

The processes are designed with scalability in mind. Whether producing a few prototypes or mass-producing electronic devices for global markets, these processes can be adapted to meet varying production volumes. This scalability brings about economies of scale, a key factor in cost optimization.

As production volumes increase, the per-unit cost of manufacturing decreases. This is because fixed costs, such as machinery, can be spread across a larger number of units. Manufacturers can achieve cost efficiencies by leveraging the benefits of mass production without compromising the quality of the end product.

- Material Efficiency and Waste Reduction

Efficient e-manufacturing processes also contribute to material optimization. Advanced technologies, such as computer-aided design (CAD) and simulation tools, enable manufacturers to optimize the use of raw materials. By precisely designing components and minimizing material waste, manufacturers can achieve significant cost savings.

Moreover, electronic manufacturing processes often involve recycling initiatives. Waste materials generated during production, such as excess solder or defective components, can be recycled. This not only reduces disposal costs but also promotes sustainability, aligning with the growing emphasis on eco-friendly practices in manufacturing.

FAQs

Q1: What is the role of surface mount technology (SMT) in electronic manufacturing processes?

A: Surface mount technology is a key aspect of these processes, involving the placement of electronic components directly onto the surface of a printed circuit board (PCB). This technology enables smaller, lighter, and more efficient electronic devices.

Q2: How does the industry address the issue of electronic waste?

A: Electronic manufacturers are increasingly adopting sustainable practices, including recycling programs and responsible disposal methods, to address the issue of electronic waste. Regulatory bodies also play a role in ensuring adherence to environmental standards.

Q3: Can electronic manufacturing processes accommodate customized designs?

A: Yes, these manufacturing processes can be tailored to accommodate customized designs. Advanced technologies, such as computer-aided design (CAD), allow manufacturers to create bespoke electronic components based on specific requirements.

Q4: What role does quality control play in electronic manufacturing?

A: Quality control is paramount in electronic manufacturing processes to identify and rectify defects during production. Rigorous testing ensures that electronic components meet industry standards and function reliably.

Q5: How do electronic manufacturers address the challenge of rapid technological obsolescence?

A: To tackle technological obsolescence, electronic manufacturers invest in research and development, staying abreast of emerging technologies. Continuous innovation and a commitment to adapting to industry trends are key strategies in addressing this challenge.

Conclusion

Electronic manufacturing processes form the backbone of our technologically driven world. Understanding the pros and cons of these processes is essential for manufacturers, consumers, and environmental advocates alike. As technology continues to evolve, so too will the methodologies and considerations within these processes.