Modern manufacturing is the trend these days. So is CNC manufacturing. The journey begins with the materials, the elemental building blocks sculpted into tangible forms by the wizardry of CNC machines. Metals, be they the stalwart steel, the lightweight aluminum, or the aerospace marvel titanium, find themselves obediently bowing to the precision of CNC processes. The CNC manufacturing machine, a maestro in its own right, transforms these raw materials with a precision that transcends the limitations of traditional craftsmanship.

Materials in CNC Manufacturing

CNC manufacturing caters to a vast array of materials, each demanding precision and finesse in its processing. Metals such as aluminum, steel, and titanium are commonly machined using CNC processes, benefitting from the technology’s ability to execute intricate designs with unparalleled accuracy. Moreover, CNC manufacturing extends its prowess to non-metal materials like plastics, composites, and even advanced materials such as ceramics.

The versatility of CNC manufacturing lies in its adaptability to various materials, making it a go-to solution for industries with diverse material requirements. Whether crafting intricate components for aerospace applications or producing precise molds for medical devices, CNC manufacturing proves its mettle across a spectrum of materials, ensuring quality and consistency.

The Process

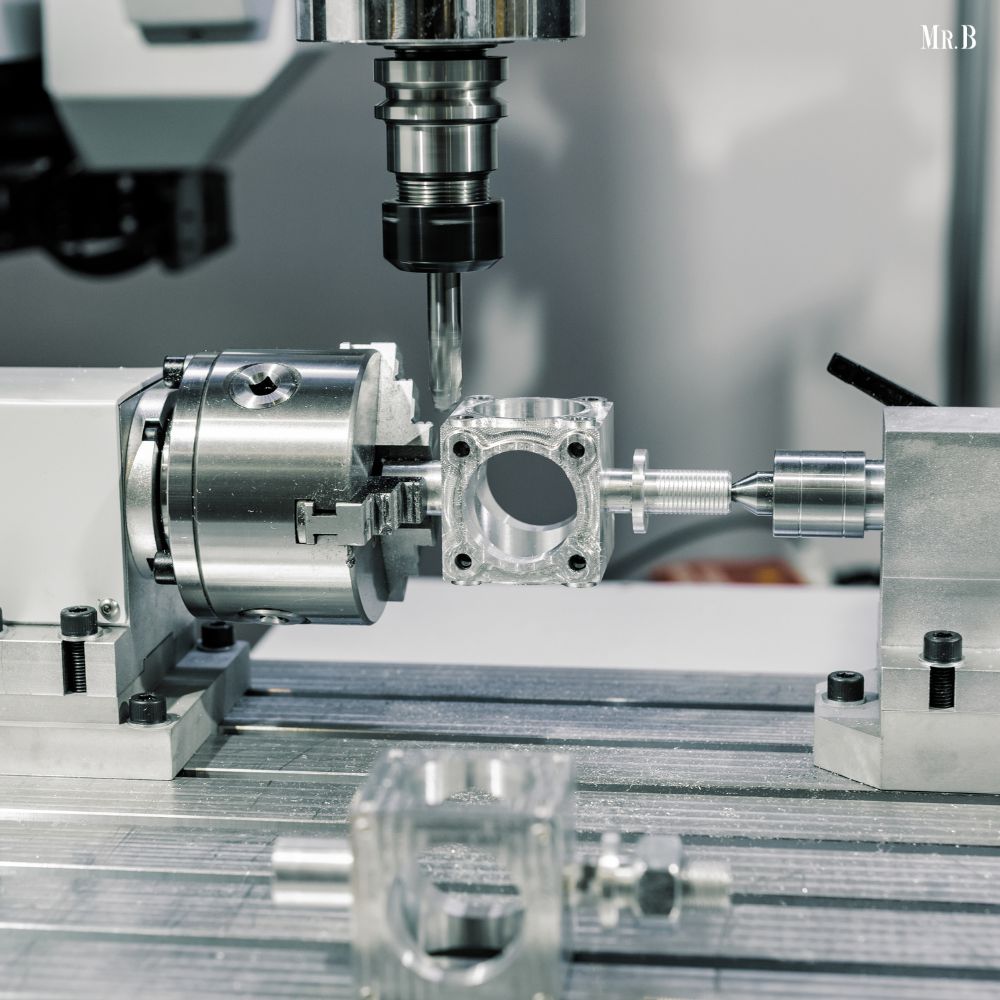

At the heart of CNC manufacturing is the automated precision achieved through computerized control. The process begins with a digital design or CAD (Computer-Aided Design) file, specifying every detail of the intended product. This digital blueprint is then translated into CNC machine instructions, known as G-code.

The CNC machine, equipped with cutting-edge tools, follows the G-code instructions with meticulous accuracy. From milling and turning to drilling and grinding, CNC machines execute complex operations with speed and repeatability. The result is a precisely crafted component that meets exact specifications, a hallmark of CNC manufacturing.

Applications

The applications of CNC manufacturing are as diverse as the materials it processes. In the aerospace industry, CNC machining is instrumental in crafting components with stringent tolerances, ensuring the safety and reliability of aircraft. Automotive manufacturers rely on CNC processes for precision parts that contribute to fuel efficiency and vehicle safety.

In the medical field, this plays a pivotal role in producing intricate surgical instruments and implant components, where precision is paramount. The electronics industry benefits from CNC technology in the fabrication of circuit boards and intricate components for cutting-edge devices. The list goes on, illustrating the pervasive influence of this type of manufacturing travels across various sectors.

Benefits of Adopting the Process:

Organizations worldwide are increasingly adopting CNC manufacturing due to its myriad advantages. One primary benefit lies in the unparalleled precision and consistency achieved through automated processes. The ability to replicate intricate designs with minimal variation ensures a high level of product quality, a critical factor in industries where precision is non-negotiable.

The manufacturing also boasts remarkable efficiency, significantly reducing lead times compared to traditional manufacturing methods. The automated nature of CNC processes minimizes human error, accelerates production cycles, and enhances overall productivity. As a result, organizations can meet market demands more swiftly and maintain a competitive edge.

Moreover, CNC manufacturing facilitates design complexity without compromising accuracy. This freedom in design is particularly valuable in industries where intricate and customized components are essential. CNC machines can effortlessly execute complex geometries and contours, enabling innovation in product design and functionality.

Reducing Production Costs

A compelling aspect that attracts organizations to CNC manufacturing is its potential for cost reduction. While the initial investment in CNC machinery and software may seem substantial, the long-term cost savings are significant and multifaceted.

1. Material Utilization:

CNC machines are adept at optimizing material usage. Through precise tool movements and cutting strategies, they minimize waste, ensuring that raw materials are utilized efficiently. This reduction in material wastage directly translates to cost savings for manufacturers.

2. Labor Efficiency:

Traditional manufacturing processes often require skilled labor for manual operations, leading to higher labor costs. In contrast, it minimizes the need for manual intervention. Once the CNC machine is programmed, it can operate autonomously, requiring minimal human oversight. This labor efficiency not only reduces costs but also mitigates the risk of errors associated with manual operations.

3. Reduced Scrap and Rework:

The precision of CNC manufacturing significantly reduces the likelihood of producing defective components. This, in turn, minimizes the need for scrap disposal and rework, both of which contribute to additional costs in traditional manufacturing settings.

4. Improved Production Speed:

Time is money in manufacturing. CNC machines operate at high speeds, executing tasks with rapid precision. The reduced production cycle times enable manufacturers to meet market demands promptly, preventing potential revenue losses due to delays.

5. Flexible Production Scheduling:

CNC manufacturing allows for easy adaptability to changes in production schedules. The ability to reprogram CNC machines quickly enables manufacturers to respond promptly to fluctuations in demand, avoiding costly disruptions associated with traditional manufacturing setups.

In essence, while the initial investment in CNC technology may seem substantial, the long-term cost benefits far outweigh the upfront expenses. The efficiency gains, material savings, and the ability to meet market demands swiftly position it as a strategic investment for organizations seeking sustainable growth and competitiveness.

Why Organizations Should Embrace CNC Manufacturing

The compelling reasons for organizations to embrace CNC manufacturing extend beyond its immediate cost-effectiveness. Here are key considerations driving the widespread adoption of CNC technology:

1. Enhanced Precision and Quality:

CNC manufacturing ensures a level of precision and quality that surpasses traditional methods. The ability to consistently produce components with tight tolerances enhances product reliability and customer satisfaction.

2. Adaptability to Industry 4.0:

In the era of Industry 4.0, where smart manufacturing and connectivity are paramount, CNC machines seamlessly integrate into digitally driven production environments. The data generated by CNC processes can be leveraged for real-time monitoring, predictive maintenance, and overall process optimization.

3. Skill Shortage Mitigation:

Traditional manufacturing often faces challenges associated with a skilled labor shortage. It mitigates this issue by relying on automated processes that require less specialized expertise. This not only addresses the skill gap but also reduces training costs.

4. Innovation in Design:

The flexibility offered by it in realizing intricate and complex designs fosters innovation. Organizations can push the boundaries of product design, introducing features and geometries that may not be feasible with traditional manufacturing methods.

5. Environmental Sustainability:

It contributes to environmental sustainability by minimizing material waste and energy consumption. The efficient use of resources aligns with global efforts to promote eco-friendly manufacturing practices, making CNC technology an attractive option for environmentally conscious organizations.

6. Competitive Advantage:

Embracing this provides organizations with a competitive edge. The ability to deliver high-quality products with greater efficiency positions companies as market leaders, fostering customer trust and loyalty.

Conclusion

CNC manufacturing stands as a cornerstone in the evolution of modern production methodologies. Its versatility, precision, and cost-effectiveness make it a strategic choice for organizations looking to navigate the complexities of contemporary manufacturing landscapes. As industries continue to embrace digital transformation, it emerges not just as a technological solution but as a catalyst for innovation, efficiency, and sustained growth.